Layout Engineering

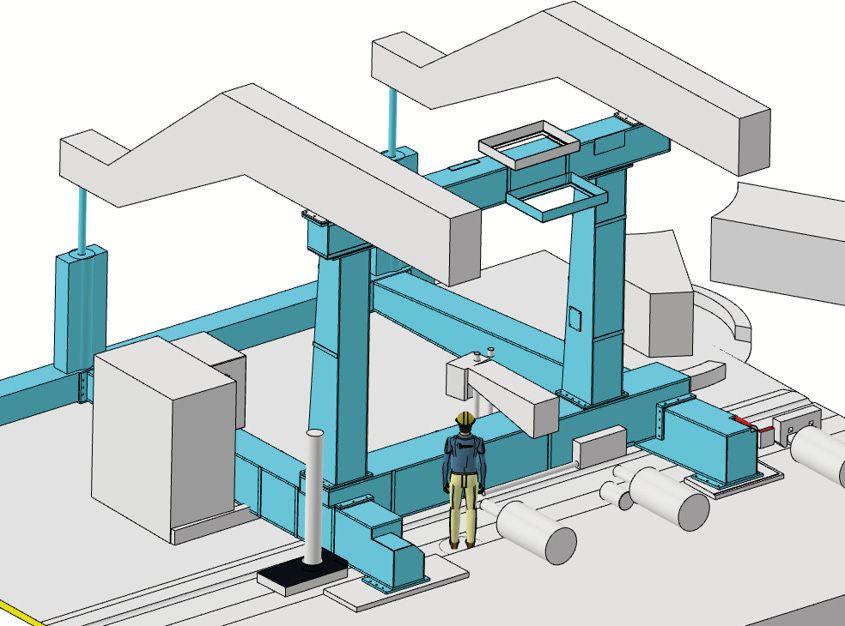

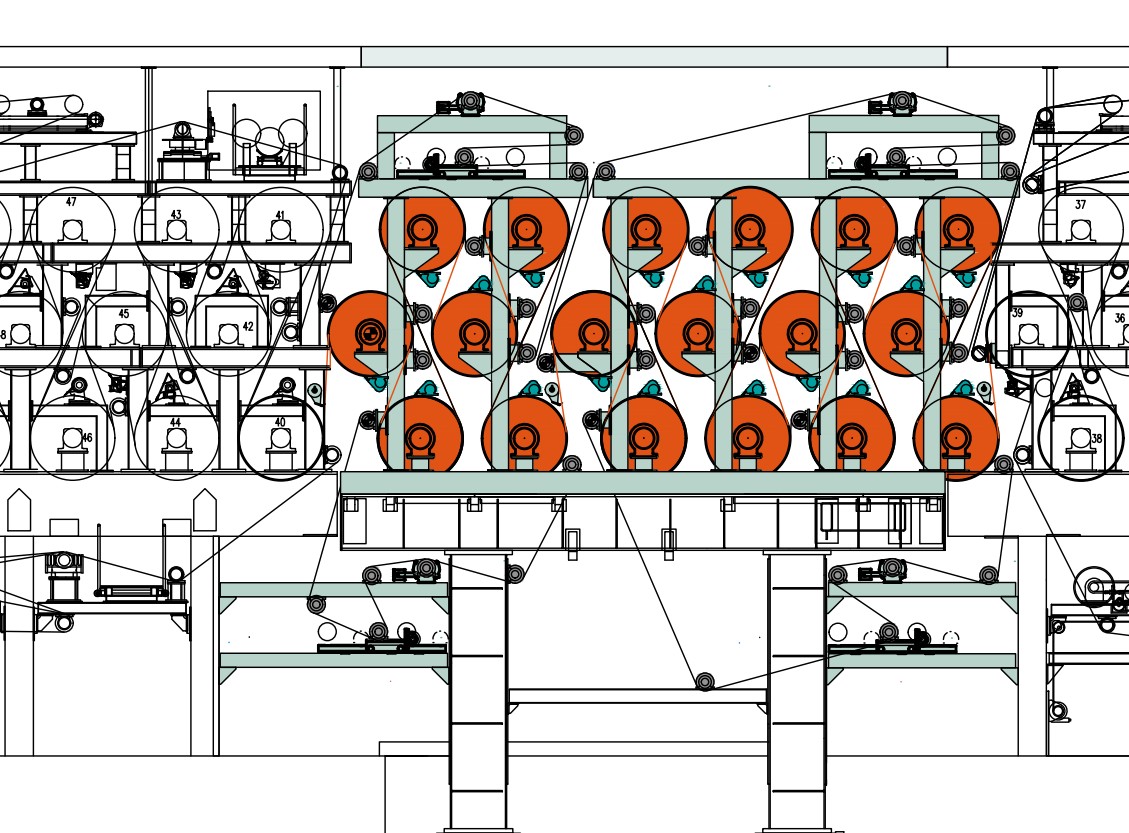

Our layout engineering services provide comprehensive solutions for industrial facility planning and optimization. We specialize in creating efficient and practical layouts that maximize space utilization and operational efficiency.

We excel at integrating second-hand equipment and structures into existing processes, ensuring seamless fit and optimal performance while maximizing your investment value.

Layout Engineering Services Include

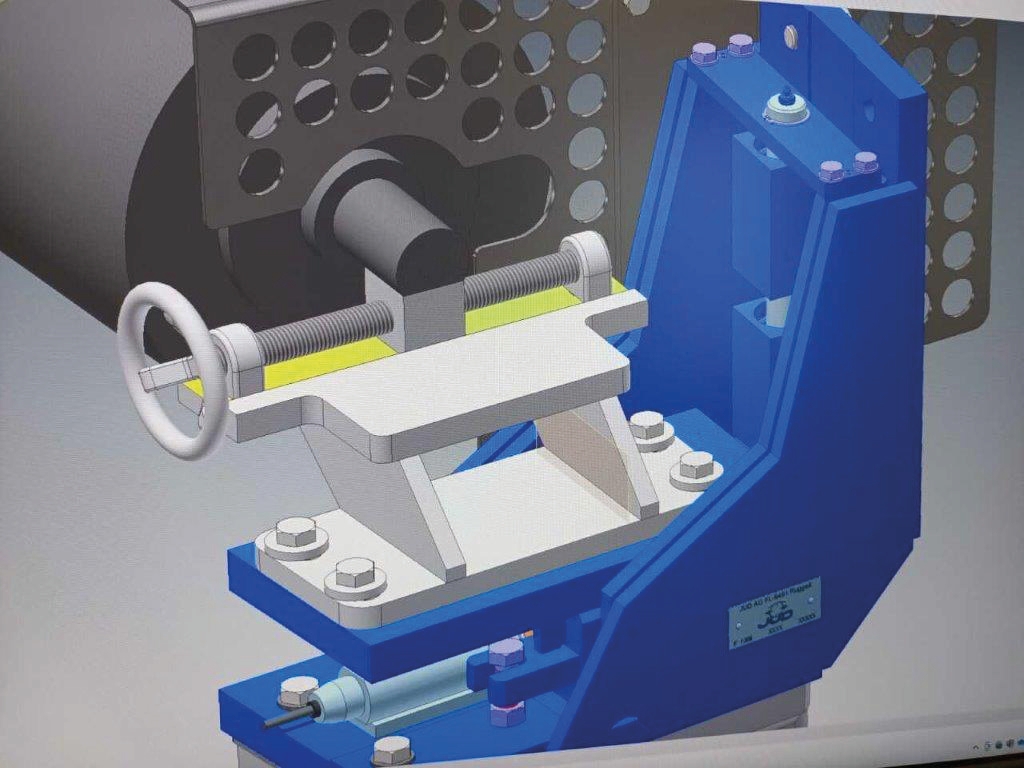

- Device placement and mechanical layout design

- Equipment positioning for optimal workflow

- Second-hand equipment and structures fitting into existing processes

- Piping route planning and optimization

- Actuator placement and positioning

- Pipe support design and placement

- Access and maintenance planning

- Space optimization studies

Our experienced engineers use modern 3D modeling tools to visualize and optimize your facility layout before any physical work begins, minimizing costly changes during installation.

Contact us